ABOUT

Showcasing electronic projects and sharing technical insights.

Capturing ideas, exploring solutions, and hopefully offering something useful to others.

BLOG

PROJECTS

ORRIS Audio System

We want someone to be able to walk up to the board, tap in a few notes, twist a few knobs, and instantly feel the joy of crafting their own music.

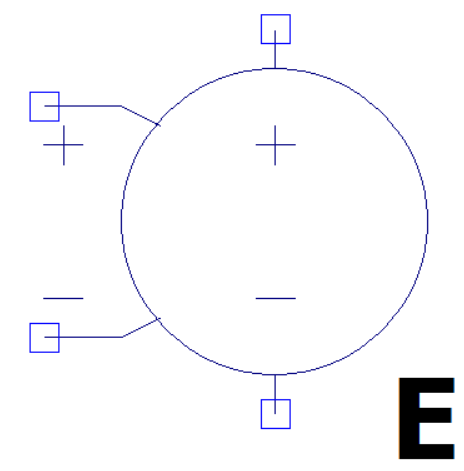

Orris is wall-mounted synth rack driven by a sequencer, which acts as the brain of the system. The sequencer triggers user-inputted notes to connected synth modules. The modules can be either synthesizers or effects modules, all controlled digitally but output analog signals. Each synth or effects module plugs into a backplane that routes analog signals to a mixer and enables inter-module audio routing via a connection matrix. In this version, the mixer simply combines the various audio signals and drives the speakers. The entire system is powered by rechargeable batteries or via USB through the power supply block. Mechanically it is equivalent in dimensions and weight to a medium-to-large sized picture frame.

This project is in the early stages of its design and I will update this website as I go in its development.

LED Dance Floor Lighting

A year before I got married, my now wife and I were figuring out how we wanted to set up a dance floor. The wedding was outdoors at my parents’ place, and luckily, there was already a large concrete slab perfect for a dance floor.

Great - floor sorted. But what about lighting?

Me, being an overconfident engineer thought: “Let’s just get some LED strip lights. Easy right?” – Wrong

In this project, I will cover:

System requirements, block diagrams, and key design choices

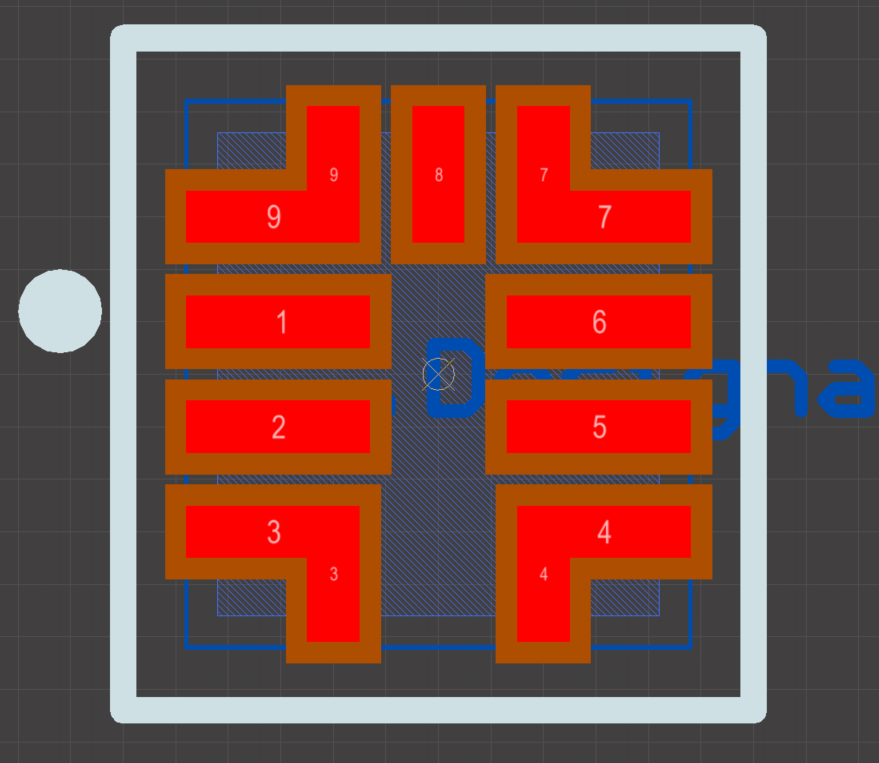

Hardware: STM32H7 microcontroller, power supplies, RGBW LED strips, digital isolators, LCD screen, custom PCBs, and more

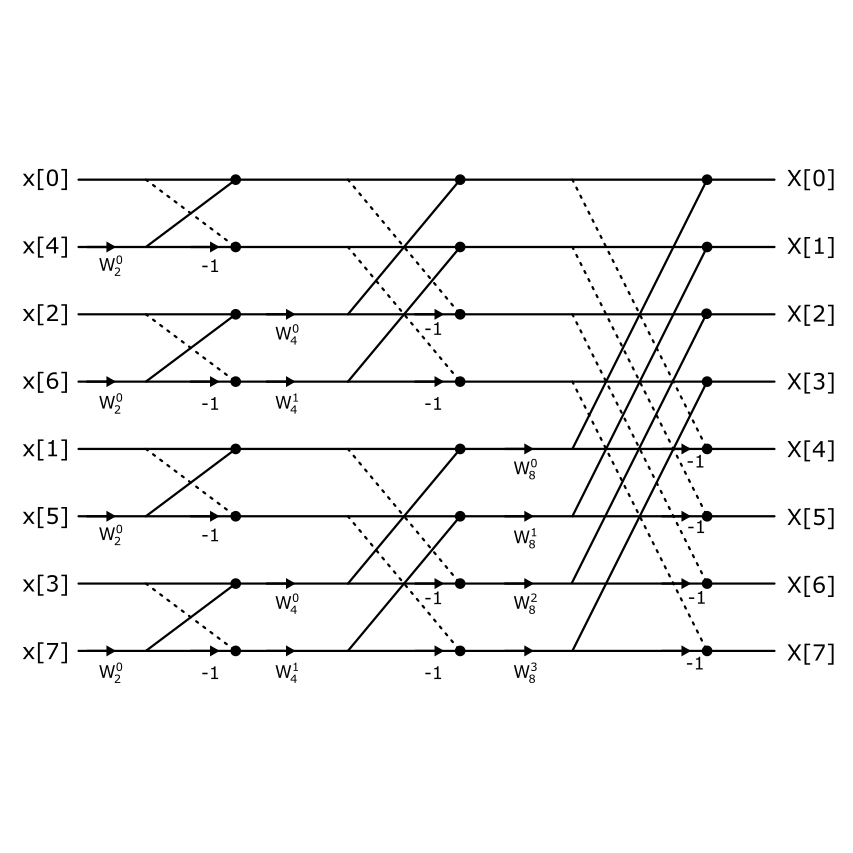

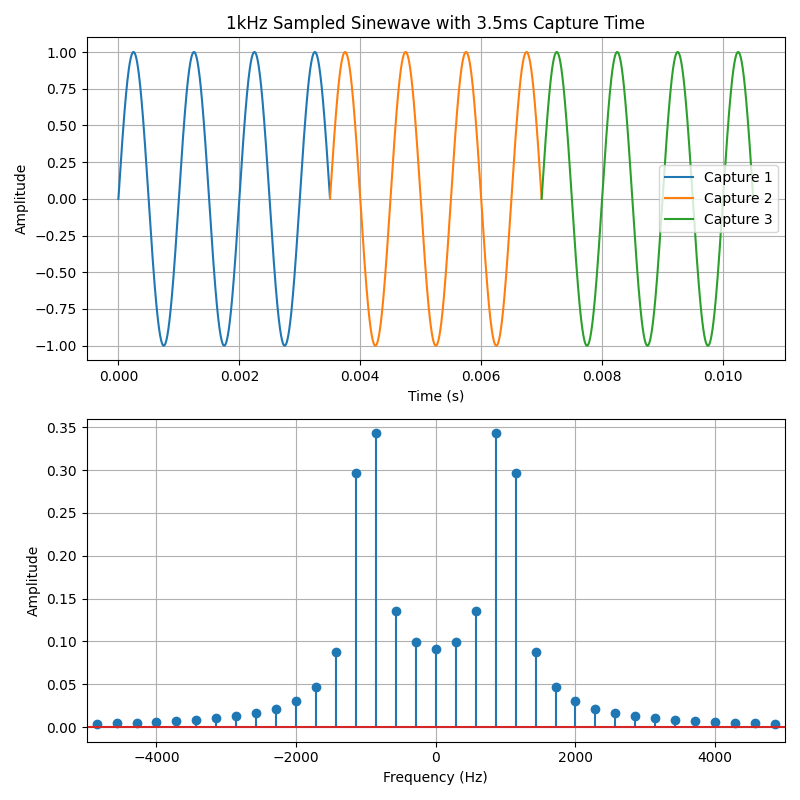

Firmware structure, design approach, and notable algorithms

Brief notes on mechanical design

FlyBeams OneWheel Lights

One day, a friend of mine - who’s way cooler than me - came to me with an idea:

“Can we put lights on the side of a OneWheel?

Of couse.

“Can we make it look cool?”

Heck yeah.

For those unfamiliar, a OneWheel is basically a motorized skateboard with a single wheel in the middle. While it comes with a front-facing light, but more lighting would help with visibility. Add some cool effects, keep the design compact and rechargeable, and hey - maybe we could even sell it.

We never got around to selling it, though. My friend got busy being cooler than ever and winning a BAFTA for his work on a game called Before Your Eyes. But we did make a working prototype.

In this project, I will cover:

System requirements, block diagrams, and key design choices

Hardware: microcontroller, battery charger, accelerometer, touch sensors, and custom PCB

Brief notes on mechanical design

Electronic Load

This was my first sizable personal project. At the time, I realized that while I had done some solid hardware design at work, I couldn’t actually show any of it in a job interview. So, I decided to build an electronic load - and do my best to make it look professional.

An electronic load felt like a great place to start: it’s relatively simple to build, and commercial bench-top models can be pretty expensive for a basic home lab setup.

I focused on optimizing accuracy for low currents (1 mA to 5 A) and aimed to support the typical operating modes: constant current, constant voltage, constant power, and constant resistance. I also wanted it to handle transient tests and allow for remote control.

In this project, I’ll cover:

System requirements, block diagrams, and key design choices

Hardware: microcontroller, constant current sink, difference amplifier, fan controller, EEPROM, LCD screen, and custom PCB

Firmware design methodology and notable algorithms